About ZanVision

ZanVision is an innovative company specializing in optoelectronics and infrared sensing technologies and products. We are committed to providing high-quality image processing solutions that are widely applied in various fields such as border surveillance, infrastructure security, and drone detection. Our R&D team consists of experts from the industry, combining years of experience and technical expertise to offer flexible and professional customized solutions for our clients.

The Cause of Purple Fringing

Purple fringing is typically caused by the optical design of the lens and the spectral response of the sensor. The lens in the device may not accurately focus light of different wavelengths onto the sensor, especially violet and blue light. Due to focusing errors, these wavelengths of light create unnatural purple halos along the edges of the image, affecting the overall visual realism.

During the calibration process, although the image signal processing (ISP) system integrated a purple fringing removal function, the actual effect was not sufficient to completely eliminate the purple fringing, resulting in suboptimal image quality.

Adjusting the Infrared Cutoff Filter: An Effective Solution

After a detailed analysis of the optical system, we proposed a solution to adjust the infrared cutoff filter (IR-CUT) and optimize its wavelength range. This adjustment significantly improved the purple fringing issue, as described below:

The Role of the Infrared Cutoff Filter

The infrared cutoff filter is primarily used to block infrared light, allowing only visible light to pass through. Positioned in the optical system, it directly influences the light wavelengths that enter the sensor. Different infrared cutoff filters have different wavelength settings, typically with a cutoff point that ensures only visible light falls within the sensor’s range.

Principle of Wavelength Range Adjustment

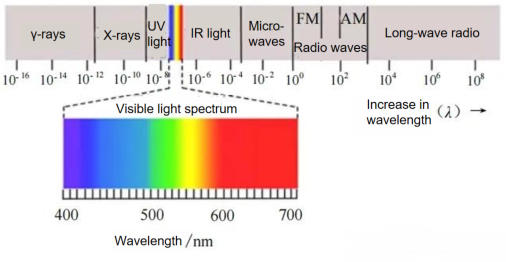

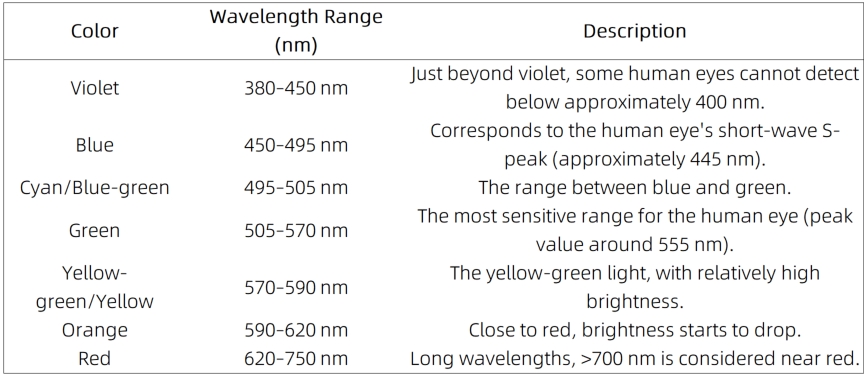

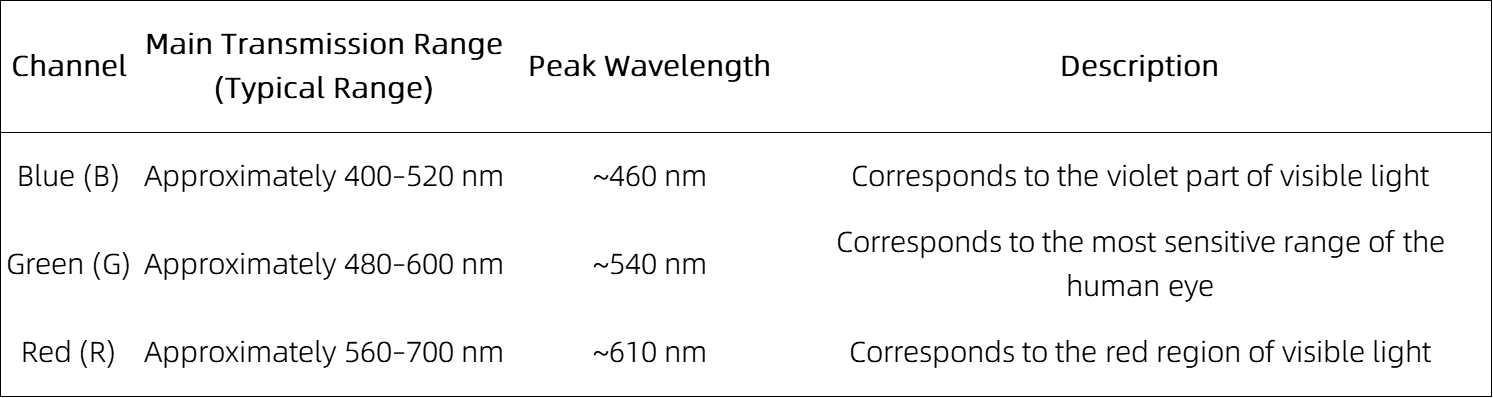

The original infrared cutoff filter had a range of 417~645nm, which was adjusted to 435~645nm. The main goal of this change was to reduce violet and blue light, particularly in the range of 417nm to 435nm. Violet light typically falls within the range of 380-450nm, and this wavelength range is a major contributor to the purple fringing effect.

By increasing the cutoff point, some of the violet-blue light in this range was filtered out, effectively reducing the short-wavelength light entering the sensor, especially the response in the B channel. This adjustment significantly improved the purple fringing issue.

Improved Effect and Advantages

The image quality after the adjustment showed a noticeable improvement. The purple fringing was effectively suppressed, and the colors along the image edges became more natural, resulting in a more realistic overall image.

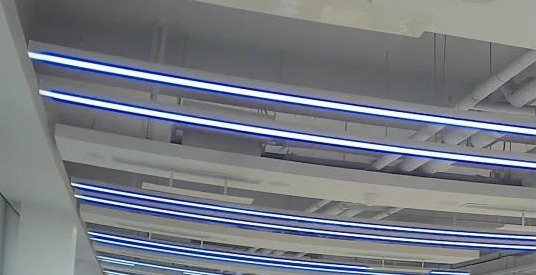

Before and After the IR-CUT Adjustment:

The results from the same device before and after replacing the IR-CUT are shown in the figure below, with clear improvement in the image quality.

Addressing the Side Effects of the Adjustment

While the adjustment to the infrared cutoff filter’s wavelength range effectively mitigated the purple fringing issue, it also introduced new challenges, particularly in the following areas:

White Balance Issues

Due to the reduction of violet-blue light in the B channel, the brightness in the B channel decreased. If the white balance is not recalibrated, the image may appear yellow or green. This occurs because the decrease in the B channel’s brightness leads to a relative increase in the R and G channels, affecting the overall color temperature.

- The visible light spectrum typically ranges from approximately 400nm to 700nm.

- R (Red), G (Green), B (Blue) channels of the CMOS sensor record these respective wavelength bands.

- Decreased Signal-to-Noise Ratio (SNR)

To compensate for the weakened signal in the B channel, the gain needs to be increased. However, this increase in gain may lead to a decrease in the signal-to-noise ratio (SNR), which can negatively impact image quality, especially in low-light conditions. This issue requires careful consideration when designing the spectral cutoff to ensure overall image quality is maintained.

Key Takeaways

By adjusting the infrared cutoff filter's wavelength range, we effectively solved the purple fringing issue, resulting in a significant improvement in image quality. This process not only integrated optical design with image processing technologies but also involved fine-tuning the overall optical system of the device. While some side effects, such as white balance shifts and decreased SNR, may arise from this adjustment, these can be minimized through proper calibration and optimization.

With its deep technical expertise and continuous innovation in core optoelectronic imaging technologies, ZanVision is committed to providing higher-quality, more precise solutions to help clients solve technical challenges and achieve optimal results in real-world applications.